7. Packaging

For more information see 'Container and Pallet Stowage Recommendations for Export Horticultural Produce', Section 11: Further Information.

7.1. Packages

7.1.1. Carton material should be of sufficient strength to withstand rough export handling conditions. The packaging must be able to support a stacking height of up to 2.5 metres (for 8’ 6” high containers) and 2.85 metres (for 9’ 6” high containers) and withstand humidity without collapsing. Carton blanks and erected cartons must be stored in accordance with manufacturer's instructions. Chilled produce unloaded in South East Asia (and other areas with similar weather conditions) inevitably becomes wet from condensation due to the high humidity in these countries.

7.1.2. A carton should be formed carefully from the fibreboard blanks, according to manufacturer's instructions. Ensure the vent blanks are removed otherwise they may become dislodged and clog up the drain outlet. Clogged drain outlets can result in quality and out-turn problems.

7.1 3. All packages must be clearly labelled with the appropriate trade description and bear the manufacturer’s statement, and in line with labelling requirements as laid down by the regulatory bodies of the importing countries. If local language is required on the label, ensure that the translation is accurate.

7.1.4. Packages should not be over packed beyond the recommended weight. Any overfill of cartons should be kept to a minimum, and should be consistent between cartons, and should be such to ensure produce does not incur “pressure” damage during transit. Any bulging of cartons should be kept within acceptable limits.

7.1.5. Where appropriate, pallet loads of cartons should be allowed to settle before loading.

7.1.6. Polystyrene boxes (eg. the 5 or 10 kg grape or broccoli box) must have integral lids, and be approved by the manufacturer for export under refrigeration.

7.1.7. The selection of packaging usually depends on product type and it may be advisable to ascertain whether there are existing designs, trialled and proven by other exporters that would suit the commodity.

7.1.8. Consideration should be given to the size of the packaging to improve utilisation of the container, without overfilling or restricting the airflow.

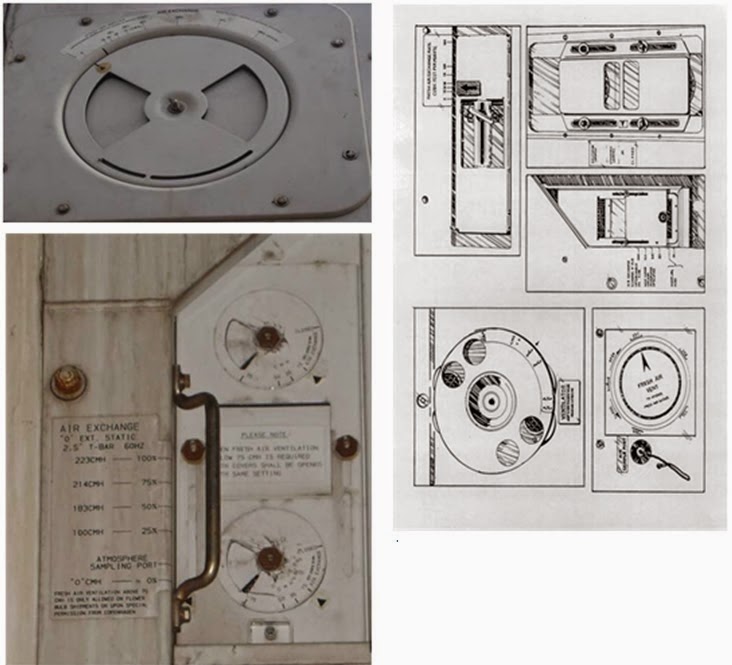

7.1.9. Although ventilation holes are usually made on the sides of the cartons, it must be borne in mind that air circulation is usually from beneath, so for optimal circulation, ventilation holes must be located at the top and bottom of the carton. Excessive ventilation may however lead to excessive weight loss, if additional wrapping or packaging is used within the cartons consideration must be given to the effect it will have on the ventilation process.

Note: Packaging vents need to be aligned for adequate airflow.

7.1.10. Dehydration of the produce can be reduced by utilising the appropriate packaging.

7.1.11. Packaging material should be chosen not only for its durability during transport but also its ability to permit the removal of respiratory heat and other gases emitted by the produce (if required).

7.2 Bulk bins

7.2.1. These bins are suitable only for produce able to be bulk stacked, e.g. apples.

7.2.2. Custom size bins make better use of the available space.

Bin sizes 1100 mm x 1100 mm and 1065 mm x 1065 mm and 1085 mm x 1117 mm (WA).

7.3. Palletising

7.3.1. Packages should remain within the pallet dimensions (i.e. no overhang) to maintain stacking strength and stability as well as ease of stowing into the container.

7.3.2. Euro-pallet 1200 mm x 1000 mm requires specifically designed cartons to maximise efficiency of use of the container volume (eg. 395 mm x 295 mm for the grape carton and 595 mm x 395 mm for the potted plant carton).

7.3.3. Custom size pallets will make more efficient use of the container volume (eg. NZ pallet 1080 mm x 980 mm for integral containers). Be aware pallet boards/slip sheets etc may cause airflow restriction.

7.3.4. Handling procedures at the point of import must be arranged.

7.4. Slip sheets

These are technically feasible but no use has been made of them for horticultural produce. Some use has been made of them in the meat industry.

If Slip Sheets are utilised, shippers should ensure that the airflow through the bottom channelling is not obstructed. Also slip sheets must end at the completion of the T-bar.

7.5. Stabilising

7.5.1. Any stabilising method used must keep the pallet firmly together to ensure ease of stowing into the container. Stabilising may be achieved by using pallet adhesive, adhesive tape, stretch wrap, shrink-wrap, stretch netting, or strapping. Right angle corner supports, of metal, fibreboard or plastic, may be used in conjunction with any of the above methods. Stabilising methods must not restrict air circulation throughout the cargo stow.