What Is a Cooling Tower?

This pamphlet will help you identify if you have a cooling tower system. It will also help you work out what type of cooling tower system you have.

Fill

All cooling tower systems contain fill in the tower. Fill is usually constructed of plastic. In some very large cooling towers it may be made of wood. The fill material allows the falling water to spread over a greater area. This increases the surface area of the water to be cooled, allowing better and more effective cooling of the water.

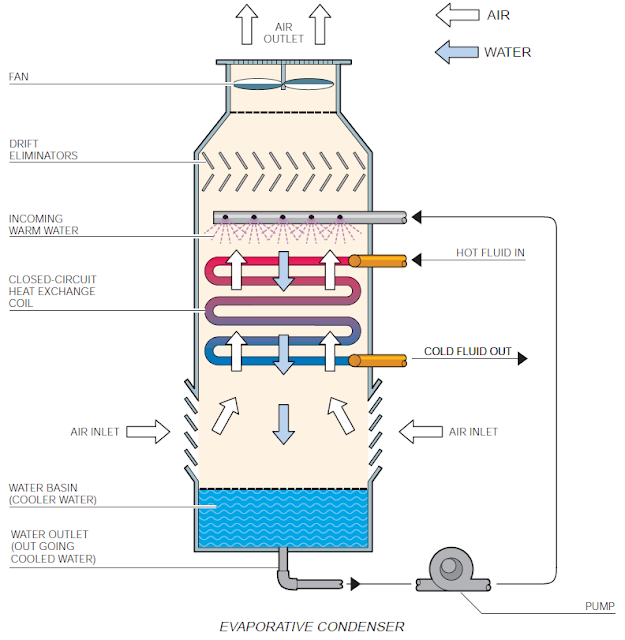

Evaporative Condensers

These units work in a similar manner to cooling towers. The cooled water is distributed over a series of pipes that contain circulating refrigerants or other fluids. Unlike cooling towers, evaporative condensers do not contain any fill material. These systems also present risks for Legionnaires’ disease and can be regarded as a type of cooling tower system.

Other Types of Cooling Systems

There are two other types of cooling systems. These are refrigerated air conditioners and evaporative coolers. These systems are not cooling towers.

Evaporative Coolers

Evaporative air coolers are also known as evaporative airconditioners or ‘swampies’. These systems use water to cool outdoor air for use inside. Evaporative coolers work in a similar way to the system the body uses to cool itself. Perspiration is evaporated from the skin by the circulating air. There has been no evidence linking evaporative coolers to cases of Legionnaires' disease.

Refrigerated Air Conditioners

These systems are also known as electric air cooled or refrigerated systems. Recirculating indoor air is cooled by being blown over a refrigerated coil. The cooled air is then redirected indoors. The refrigerant in the coil is cooled outside by a fan or natural convection.

Cases of Legionnaires' disease are not associated with refrigerated or air cooled systems.

Cooling towers are used in air conditioning systems, for refrigeration or to cool materials in industrial processes. Cooling towers are devices that use surrounding air to cool water. A cooling tower system may contain one or more cooling towers that all use the same recirculating water. The cooling tower system also includes any machinery used to operate the tower and any tanks, pipes or valves connected to the system.

How does a cooling tower work?

In a cooling tower, a fan pushes or draws air from the atmosphere into the tower to cool recirculating water. Warm water, that has removed heat from an air conditioning, refrigeration or industrial process, enters the top of the tower. As the water falls through the tower fresh air is forced through it. This fresh air cools the water. The cooled water then falls to a storage basin before being recirculated through the system again. When the water is recirculating through the system it gathers heat from an air conditioner or industrial process before returning to the top of the tower.

How does a Cooling Tower System Spread Legionella?

When air is drawn or forced through a cooling tower it collects water droplets. As the air leaves the tower it carries aerosols into the environment. Sometimes these aerosols may be contaminated with Legionella bacteria.

The air that contains the aerosols is called spray drift. If the spray drift is contaminated with Legionella and breathed in by susceptible people, these people may develop Legionnaires' disease.

Physical and chemical agents can kill Legionella bacteria in the cooling tower water. These agents are called biocides.

It is important that the water in cooling towers is treated with appropriate biocides to minimise the risk of Legionella growing in and contaminating the tower. Physical barriers such as drift eliminators can also minimise the amount of spray drift that can escape from a tower.

Types of cooling towers

There are three main types of cooling towers:

• Induced draught counter flow cooling tower.

• Forced draught counter flow cooling tower.

• Induced draught cross flow cooling tower.

• Forced draught cross flow cooling tower.

Cooling towers come in many different shapes and sizes. Some may be as large as a three storey building, while others may only be 1.5 metres high.

Induced Draught Counter Flow Cooling Tower

This type of tower is very common. It can be identified by the fan at the top of the tower. The fan pulls air up through the tower in the opposite direction to which the water is falling. The air usually enters the tower through inlet louvres on the sides of the tower.

Forced Draught Counter Flow Cooling Tower

In a forced draught counter flow cooling tower, the water is cooled by air that is forced through the falling water and out through the top of the tower.

Induced Draught Cross Flow Cooling Tower

In an induced draught cross flow cooling tower, the fan is also mounted on the top. However in this type of tower the fan draws or induces air across the water that is falling from the top of the tower to the basin.

Forced Draught Cross Flow Cooling Tower

In a forced draught cross flow cooling tower the fan is mounted on one side of the tower. The fan forces air horizontally across the tower through the water that is falling from the top of the tower to the basin via the fill.

This pamphlet will help you identify if you have a cooling tower system. It will also help you work out what type of cooling tower system you have.

Fill

All cooling tower systems contain fill in the tower. Fill is usually constructed of plastic. In some very large cooling towers it may be made of wood. The fill material allows the falling water to spread over a greater area. This increases the surface area of the water to be cooled, allowing better and more effective cooling of the water.

Evaporative Condensers

These units work in a similar manner to cooling towers. The cooled water is distributed over a series of pipes that contain circulating refrigerants or other fluids. Unlike cooling towers, evaporative condensers do not contain any fill material. These systems also present risks for Legionnaires’ disease and can be regarded as a type of cooling tower system.

Other Types of Cooling Systems

There are two other types of cooling systems. These are refrigerated air conditioners and evaporative coolers. These systems are not cooling towers.

Evaporative Coolers

Evaporative air coolers are also known as evaporative airconditioners or ‘swampies’. These systems use water to cool outdoor air for use inside. Evaporative coolers work in a similar way to the system the body uses to cool itself. Perspiration is evaporated from the skin by the circulating air. There has been no evidence linking evaporative coolers to cases of Legionnaires' disease.

Refrigerated Air Conditioners

These systems are also known as electric air cooled or refrigerated systems. Recirculating indoor air is cooled by being blown over a refrigerated coil. The cooled air is then redirected indoors. The refrigerant in the coil is cooled outside by a fan or natural convection.

Cases of Legionnaires' disease are not associated with refrigerated or air cooled systems.

Cooling towers are used in air conditioning systems, for refrigeration or to cool materials in industrial processes. Cooling towers are devices that use surrounding air to cool water. A cooling tower system may contain one or more cooling towers that all use the same recirculating water. The cooling tower system also includes any machinery used to operate the tower and any tanks, pipes or valves connected to the system.

How does a cooling tower work?

In a cooling tower, a fan pushes or draws air from the atmosphere into the tower to cool recirculating water. Warm water, that has removed heat from an air conditioning, refrigeration or industrial process, enters the top of the tower. As the water falls through the tower fresh air is forced through it. This fresh air cools the water. The cooled water then falls to a storage basin before being recirculated through the system again. When the water is recirculating through the system it gathers heat from an air conditioner or industrial process before returning to the top of the tower.

How does a Cooling Tower System Spread Legionella?

When air is drawn or forced through a cooling tower it collects water droplets. As the air leaves the tower it carries aerosols into the environment. Sometimes these aerosols may be contaminated with Legionella bacteria.

The air that contains the aerosols is called spray drift. If the spray drift is contaminated with Legionella and breathed in by susceptible people, these people may develop Legionnaires' disease.

Physical and chemical agents can kill Legionella bacteria in the cooling tower water. These agents are called biocides.

It is important that the water in cooling towers is treated with appropriate biocides to minimise the risk of Legionella growing in and contaminating the tower. Physical barriers such as drift eliminators can also minimise the amount of spray drift that can escape from a tower.

Types of cooling towers

There are three main types of cooling towers:

• Induced draught counter flow cooling tower.

• Forced draught counter flow cooling tower.

• Induced draught cross flow cooling tower.

• Forced draught cross flow cooling tower.

Cooling towers come in many different shapes and sizes. Some may be as large as a three storey building, while others may only be 1.5 metres high.

Induced Draught Counter Flow Cooling Tower

This type of tower is very common. It can be identified by the fan at the top of the tower. The fan pulls air up through the tower in the opposite direction to which the water is falling. The air usually enters the tower through inlet louvres on the sides of the tower.

Forced Draught Counter Flow Cooling Tower

In a forced draught counter flow cooling tower, the water is cooled by air that is forced through the falling water and out through the top of the tower.

Induced Draught Cross Flow Cooling Tower

In an induced draught cross flow cooling tower, the fan is also mounted on the top. However in this type of tower the fan draws or induces air across the water that is falling from the top of the tower to the basin.

Forced Draught Cross Flow Cooling Tower

In a forced draught cross flow cooling tower the fan is mounted on one side of the tower. The fan forces air horizontally across the tower through the water that is falling from the top of the tower to the basin via the fill.